Pre-engineered building

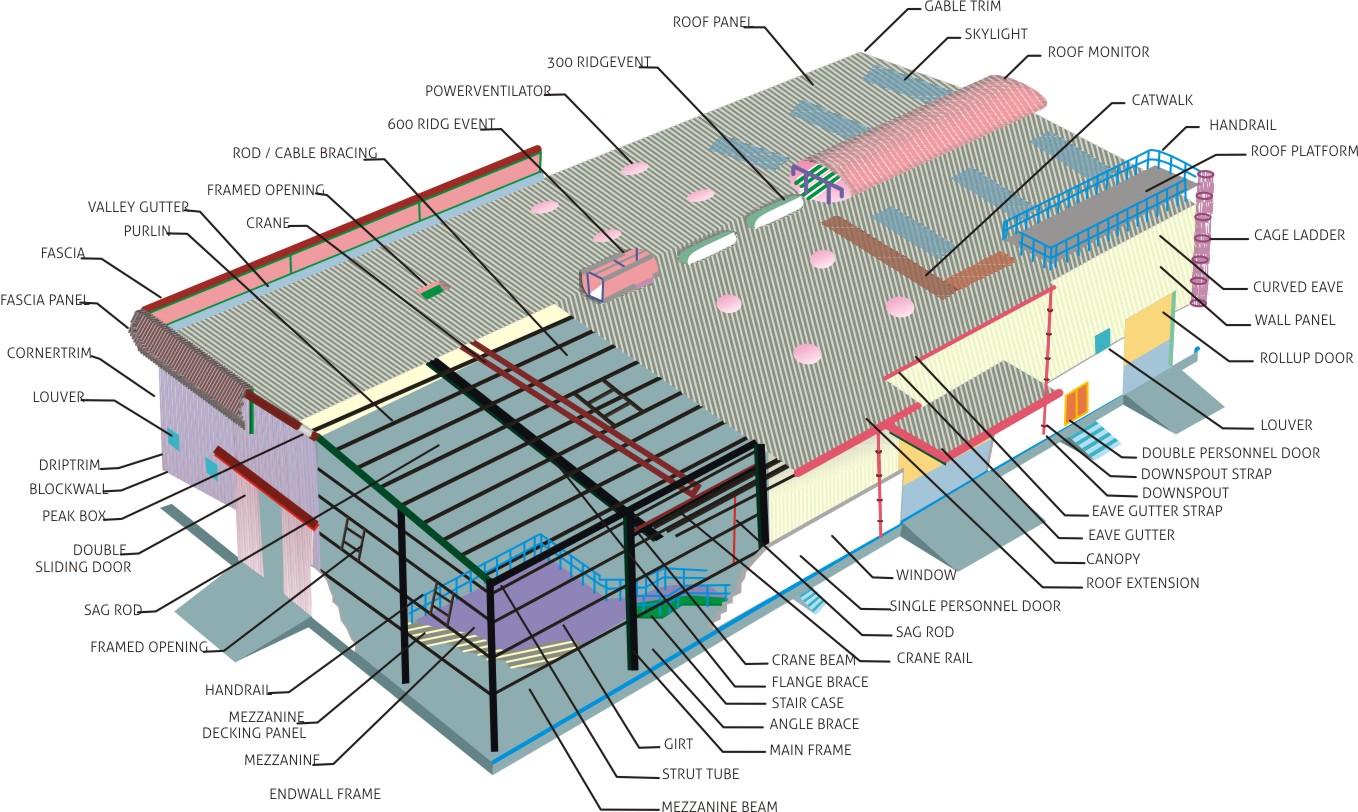

1) In structural engineering, a pre-engineered building (PEB) is designed by our team members, to be fabricated using best suited inventory of raw materials available from all sources and manufacturing methods that can efficiently satisfy a wide range of structural and aesthetic design requirements. Within some geographic industry sectors these buildings are also called pre-engineered metal buildings (PEMB) or, as is becoming increasingly common due to the reduced amount of pre-engineering involved in custom computer-aided designs, simply engineered metal buildings (EMB).

2) Standardized engineering designs for buildings were first marketed as PEBs. Historically, the primary framing structure of a pre-engineered building is an assembly of I-shaped members, often referred to as I-beams. In pre-engineered buildings, the I-beams used are usually formed by welding together steel plates to form the I-section. The I-beams are then field-assembled to form the entire frame of the pre-engineered building. Some manufacturers taper the framing members according to the local loading effects. Larger plate dimensions are used in areas of higher load effects. Our designer will design as per above said matter consideration and implementation.

3) Typically, primary frames are 2D type frames, our team may be analyzed using two-dimensional techniques. additionally, we are doing Advances in computer-aided design technology, materials and manufacturing capabilities have assisted a growth in alternate forms of pre-engineered building such as the tension fabric building and more sophisticated analysis (i.e. three-dimensional)

4) Aluminium composite panels (ACP), Steel sheet, wood, precast concrete, masonry block, glass curtain wall or other materials are considering by us used for the external cladding of the building.

5) Pre-engineered building manufacturers and designer have developed pre-calculated tables for different structural elements in order to allow designers to select the most efficient I beams size for their projects. In order to accurately design a pre-engineered building, engineers consider and designed as per the clear span between bearing points, bay spacing, roof slope, live loads, dead loads, collateral loads, wind uplift, deflection criteria, and internal crane system.

6) An efficiently designed pre-engineered building can be lighter than the conventional steel buildings by up to 30%. Lighter weight equates to less steel and a potential price savings in structural framework.

PROJECT MANAGEMENT

We are doing the practice of initiating, planning, executing, controlling, and closing the work with our team to achieve specific goals and meet specific success criteria at the specified time.

PROJECT EVALUATION

a. We are doing a systematic and objective assessment of a new proposed project, our aim

is to determine the relevance and level of achievement of project objectives, development effectiveness, efficiency,

impact and sustainability.

b. Our team will be evaluating the project in terms of design, material, manpower, cost and execution.

PROJECT ESTIMATION

a. Estimating is a critical part of project planning, involving a quantitative estimate of project costs, resources or duration.

b. Our team will be workout estimate based on duration of work, items involved in the project and price of materials on the market.

PROJECT DRAWING PREPARATION

a. As an interior designer, we need to be able to understand the relationships between materials, color, lighting and texture and the final

effect we create on a particular space. This kind of knowledge is both artistic and technical skill we are thinking and implementing.

b. PREPARATION OF SHOP DRAWINGS: Shop drawings are prepared following a review of the drawings, specifications and contract documents.

Shop drawings may be required to be submitted at the time of submission of final design drawings. (2D & 3D drawings.)

- SUBMISSION OF QUOTATION / ESTIMATION / OFFER

- WORK ORDER/PO RECEIVED FROM CLIENT

- PROCUREMENT

- EXECUTION

- START THE EXECUTION Of WORK (we are undertaking the following given list of works)

- All types of PEB works with Turnkey Project with good quality Industrial, Factories, showrooms, office, Institutions, IT sectors, Mall, Pharmaceutical, Hotels, warehouse, Residential Homes, Individual Villas, Apartment Buildings, Farmhouse, Commercial buildings, Institutional, Retail outlet(petrol bunk), and More…. Whatever may be the requirements like construction work or full design with construct package .we would deal with it and deliver you the finished product, door step services are available throughout TamilNadu, with quality work at best price for your convenience. etc., with 2D & 3D designing,

- COMMISSIONING AND HANDING OVER TO CLIENT

- MOST VALUABLE AND DEDICATED SERVICE TO THE CUSTOMER BY OUR WELL QUALIFIED TEAM OF CIVIL ENGINEERS.

- TREATING EVERY PROJECT AS OUR FIRST AND PUT ALL THE RIGHT EFFORT AS WE CAN

- ALL THE EFFORTS OF THE COMPANY FOR ENSURING BEST QUALITY PRODUCTS FOR THEIR CUSTOMERS WHICH HAS ENABLED THEM TO BUILD LONG LASTING BUSINESS RELATIONSHIPS WITH THEIR CLIENTS.